Smart + UV Sterilisation Thermometer

A thermometer designed for longevity to substantially reduce E - Waste through hospitals or healthcare centres. Millions of thermometers are consumed and discarded in healthcare centres specially hospitals. Patients that enter for prolonged treatment are provided with a new thermometer, which is dedicated to the respective individual throughout his/her hospital stay and later is discarded. Being an inexpensive electronic device, it is easy to replace and rather necessary as it is not designed for prolonged use and sterilisation. Equipments such as ultrasound or surgical tools are not discarded after use as they are high in cost and most importantly are designed for sterilisation.

Industrial Design | 02 weeks | December 2021

Managing Waste by Design

Type: Submission Assessment [Semester 04]

Time: 02 weeks

Team: Individual Project

Brief

E-Waste is a major global problem often shadowed by the established recycling processes of valuable electronic products such as computers, air conditioners, washing machines, etc. Recycling electronics with less value is not financially beneficial for individuals but largely is environmentally harmful. This project was curated to tap into unthought categories of such invaluable electronics that are generated and discarded at great masses ending up in landfills to leach out harmful contaminants throughout their everlasting decomposition.

Contents

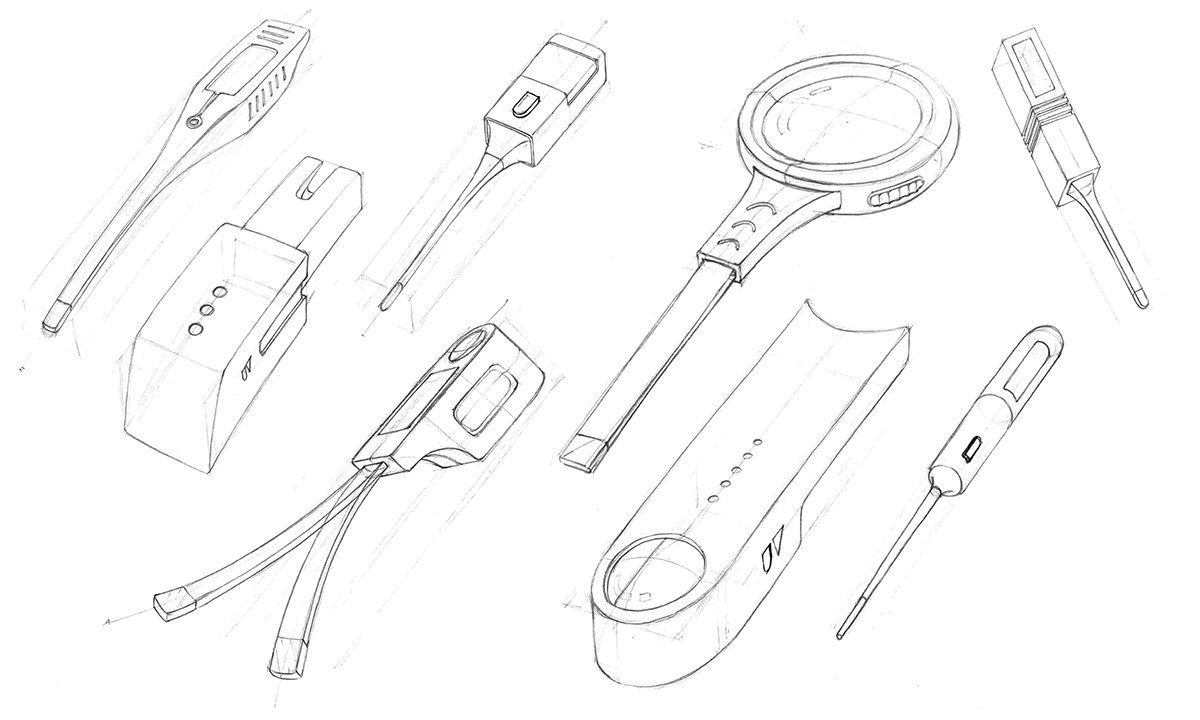

Story Board | Problems & Opportunity Areas | Ideation | Final Concept

Storyboarding

The above story board gives an understanding of how thermometers are purchased, used and then discarded due to unsterile conditions. This depiction is rather progressive of the products lifecycle but gives a clear idea of problem statements such as sterilisation & improper disposal. For a health centre setting, where the aim is reusability for several people, the problem areas need to be addressed on the highest level.

Overview

Sterility | Longevity | End life cycle

The Lotus Blossom Research Chart below, helps get a more holistic view over the topic ensuring all problem areas are identified.

Problem & Opportunity Area Delineation

Only 10% of e-waste is recycled each year out of which 9.2% is computer waste.

Mercury Thermometers: Banned due to hazardous element.

Toxic | Fragile | Inaccurate | Time consuming

Opportunity Areas

1] How can I increase resilience?

2] How can I increase usability?

3] How can the product maintain sterile conditions?

4] Should it elevate usability despite its simple function?

5] How can I add Inclusivity?

Product

UV Sterilisation Thermometer

360 degree Led indicators not only ass to aesthetics but also act as simple modes of communication.

Inclusivity

Communication & Visual Aids

Led indicators not only add to aesthetics but is a mode of communication between the user and the product. Each led colour depiction conveys simple messages, such as green & red indicating safe or unsafe to use respectively. Colours can also help depict fever levels with ease for the visually impaired.

Colour & Communication

Product Dynamics

Modularity & Function

Modularity introduces versatility, portability and most importantly: Efficient sterilisation.

A still displaying the disassembled components of the UV Thermometer

With multiple mounting points, the thermometer can be installed at multiple locations, ideal for domestic patients needing special care.

With a dedicated battery, the thermometer is designed for portability maintaining sterile conditions throughout.

The primary probe & casing are designed to withstand standard medical sterilisation [ISO 22441:2022

Sterility

The definition of sterile states absence of bacteria or other living microorganisms. Individuals going through treatment are vulnerable to infections through unsterile medical equipment. Improper storage of medical equipment is the most common area of concern in hospitals. The Smart+ UV Thermometer encompasses UVC (100-280nm) emitters which deplete 100% of living organisms within minutes. Although it is not absent of foreign debris which requires standard medical sterilisation after use, it eliminates the risk of infections.

Internals

Component Structure and Assembly

Modularity helps contribute to the identified problem statements making the product uniquely functional, but it also creates complexities in areas such as integration, fitment & reliability.

Exploded Views

Exploded view of the UV sterilisation chamber. It displays every detailed component such as screws, fitments \ interlocks, wires & gaskets.

Exploded view of the light weight primary probe and casing.

Four magnets embedded into the casings mouth guide the primary probe towards a perfect fitment.

Seamless Power Transfer

The connector train is essential for power transfer between dedicated batteries of the UV casing and the primary probe. Upon contact, not only does it charge but also sends signals to the primary PCB present inside the UV casing [highlighted in green], bringing all led's to equilibrium syncing them with the sterilisation process. A falsely placed probe will not be detected and the UV casing led indicator will convey this using rapid blinking.

Process

User Flow

Below are representations of the products flow in multiple scenarios. It mainly focuses on communication & visual aids using the led colour patterns or display.

Product and Interaction

UV Chamber Sterilisation Flow

Above is a simple five step depiction of the sterilisation process starting after use to ready to use. After the thermometer is used by a patient, it is wiped or washed before being placed into the UV chamber. The Chamber senses a removed and places probe and starts the sterilisation process indicated by a bright red colour in its led's. The colour gradually changes from red to orange, yellow and eventually green. this colour change also indicates the sterilising process %. The UV intensity slowly reduces throughout the process and eventually shuts off before the probe is removed again to avoid UV contact with the users skin. With set intervals, the UV chamber constantly sterilises the probe even when not in frequent use to maintain high sterility.

Primary Probe Interface

The probe interface is probably the most important aspect of the product. A long wide display provides higher visibility along with a subtle curvature which provides the user a slightly wider viewing degree. The displays matt texture prevents glaring reflections making it easier to view its readings at any angle. With white text and a black background, it provides the highest viewing contrast. Animated icons add character to the overall product also contributing to the users perception and mood.

Product Scenario

The display text maintains its bright white colour for high contrast, it syncs with the led light strip on the probe to visually guide a user to estimate his/her temperature reading. This feature that introduces inclusivity strongly aids those with visual impairments. With its 360 degree light strip, it also creates awareness for additional people present with the user eliminating their need of viewing the temperature reading unless serious.